In this chapter, we present a realistic GMP pharmaceutical example to demonstrate the complete Monte Carlo workflow — from defining inputs to interpreting results.

A Quality Control laboratory is validating a new process for producing tablets containing an Active Pharmaceutical Ingredient (API).

The target assay is 100.0% with specifications:

Based on historical data and expert estimates:

| Input Variable | Distribution | Parameters | Source |

|---|---|---|---|

| API Weight (mg) | Normal | mean = 100.5, sd = 1.2 | Production data |

| API Label Claim (mg) | Normal | mean = 100.0, sd = 0.5 | Production data |

| Purity (fraction) | Uniform | min = 0.985, max = 1.00 | Certificate of Analysis |

Note: “API Label Claim” refers to the declared API content (mg), not the total tablet mass.

The assay is calculated using the ratio of API weight to API label claim, multiplied by purity and converted to a percentage:

Assay(%) = (API_weight / API_LabelClaim) * Purity * 100

set.seed(123)

# Number of simulations

N <- 100000

# NOTE ON VARIABLES:

# - API_weight: measured API content per tablet (mg)

# - API_LabelClaim: declared API content (mg), not total tablet mass

# - Purity: assay purity (fraction), used as correction factor

# 1) Random inputs (choose realistic values so that assay ~ 100%)

API_weight <- rnorm(N, mean = 100.5, sd = 1.2) # mg measured API

API_LabelClaim <- rnorm(N, mean = 100.0, sd = 0.5) # mg label claim (API)

Purity <- runif(N, min = 0.985, max = 1.000)

# 2) Transfer equation

Assay <- (API_weight / API_LabelClaim) * Purity * 100

# Quick sanity-check on center and spread

mean_assay <- mean(Assay)

sd_assay <- sd(Assay)

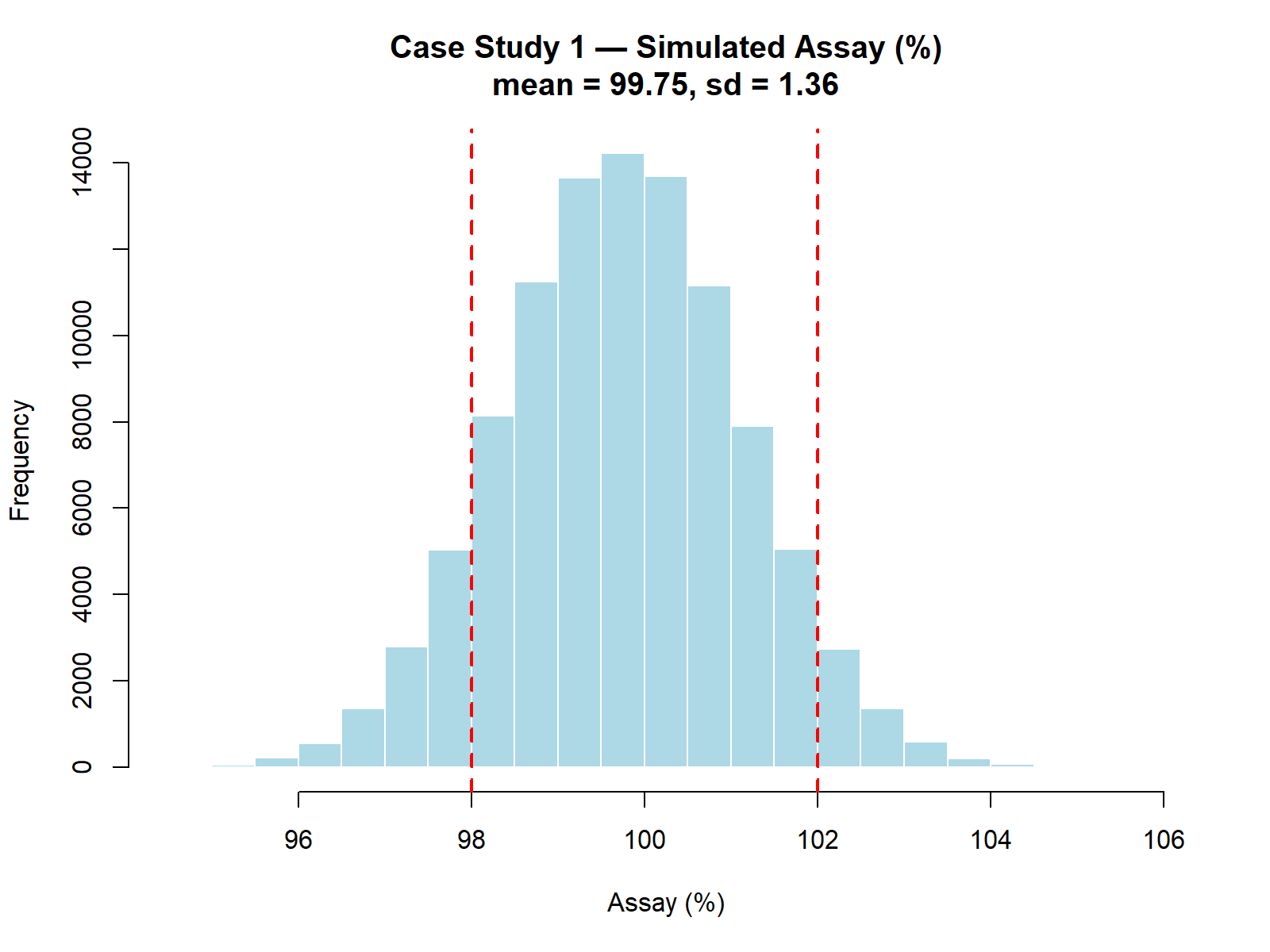

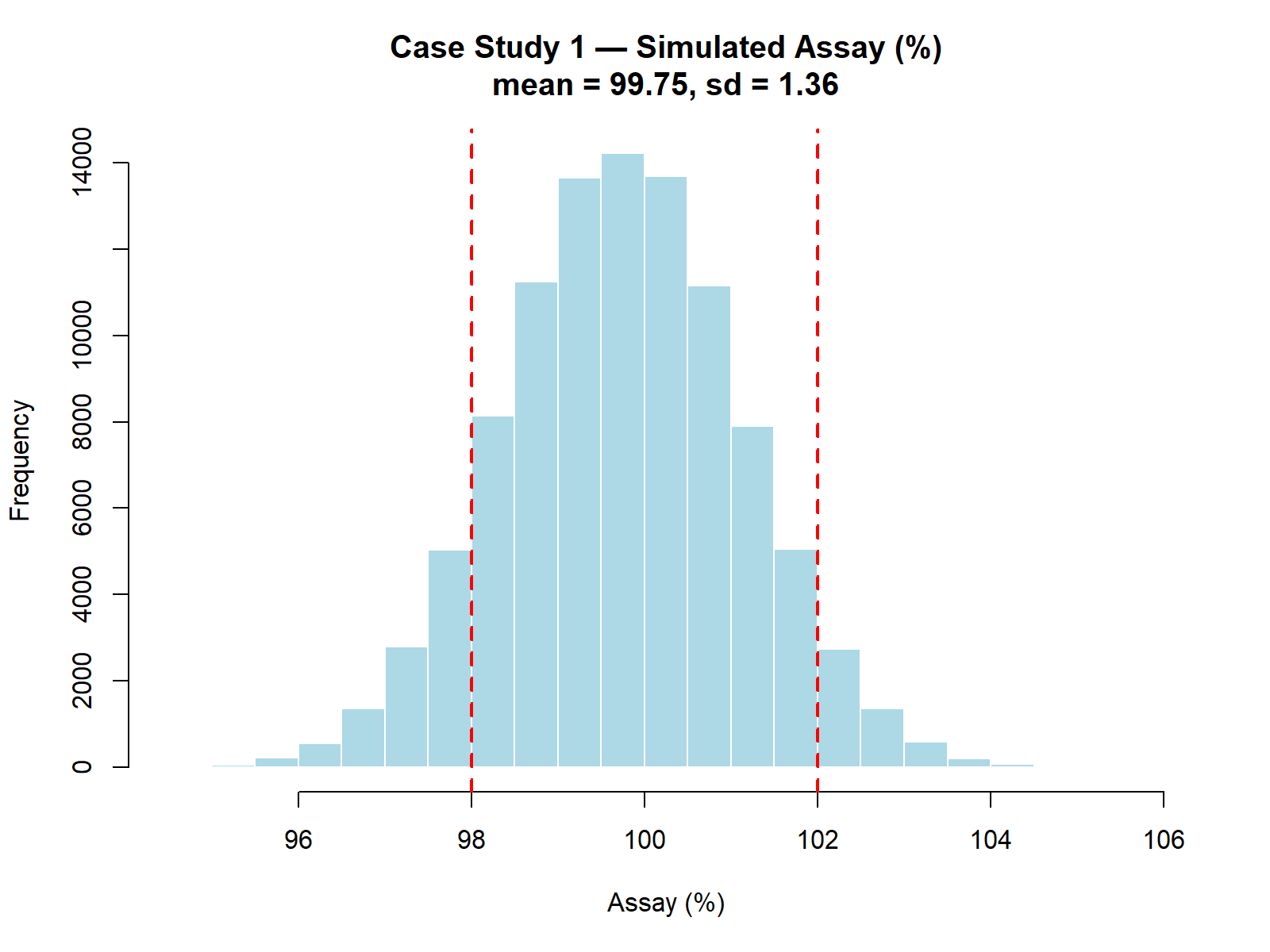

# 3) Histogram with specs

hist(Assay,

main = sprintf("Case Study 1 — Simulated Assay (%%) — mean=%.2f, sd=%.2f", mean_assay, sd_assay),

xlab = "Assay (%)",

col = "lightblue",

border = "white")

abline(v = c(98, 102), col = "red", lwd = 2, lty = 2)

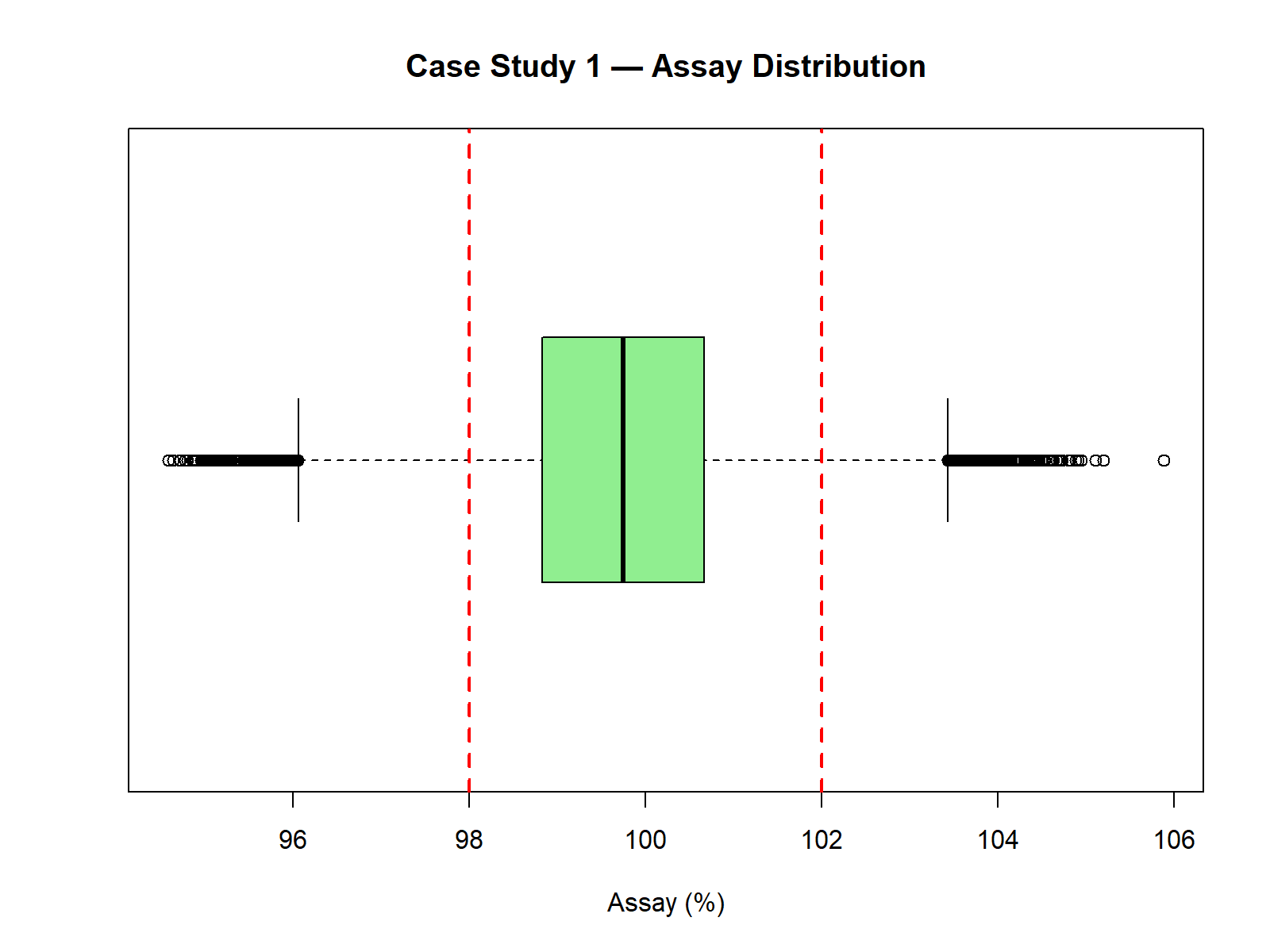

# 4) Boxplot

boxplot(Assay, horizontal = TRUE,

main = "Case Study 1 — Assay Distribution",

col = "lightgreen")

abline(v = c(98, 102), col = "red", lwd = 2, lty = 2)

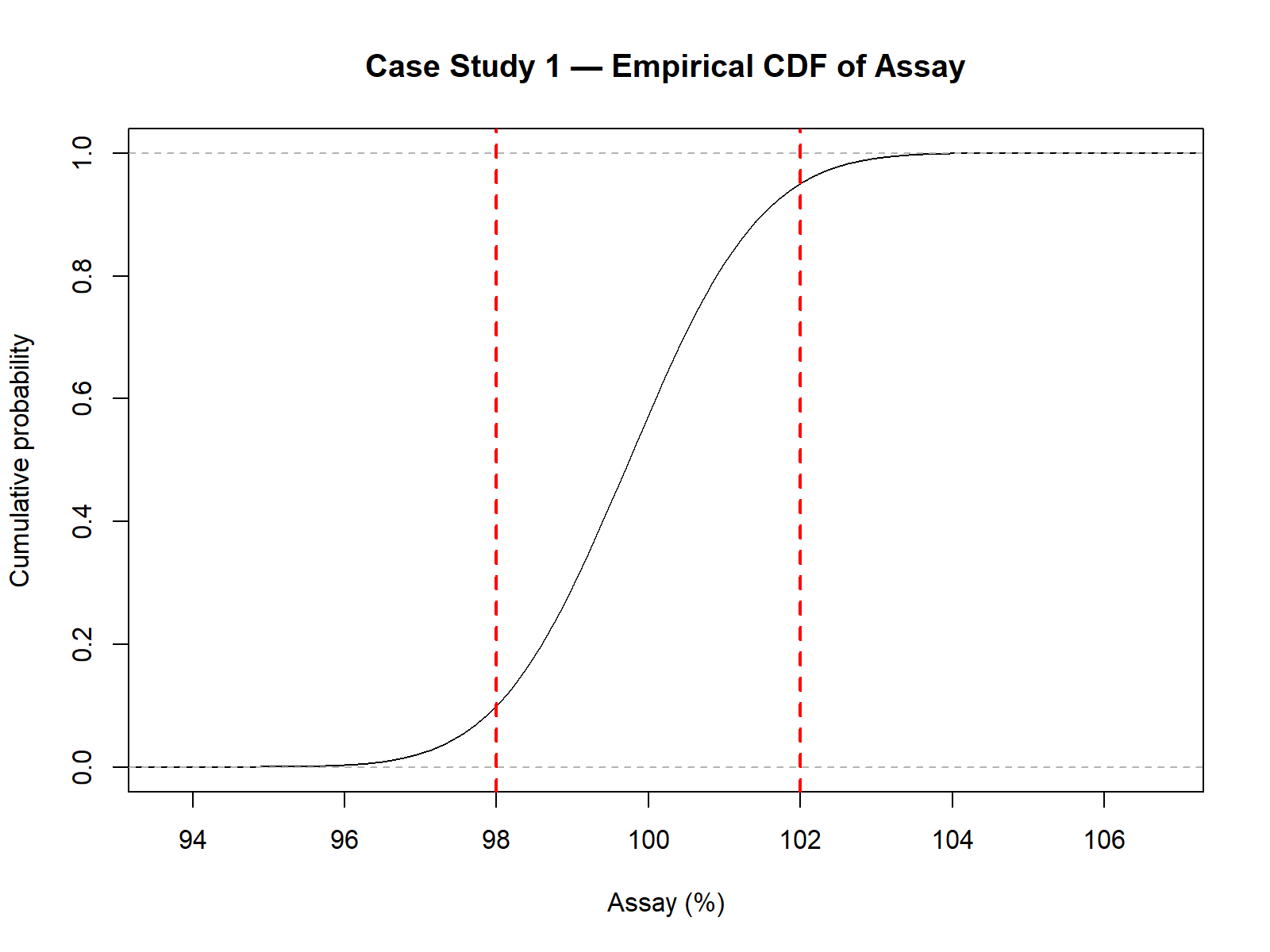

# 5) ECDF

plot(ecdf(Assay),

main = "Case Study 1 — Empirical CDF of Assay",

xlab = "Assay (%)",

ylab = "Cumulative probability")

abline(v = c(98, 102), col = "red", lwd = 2, lty = 2)

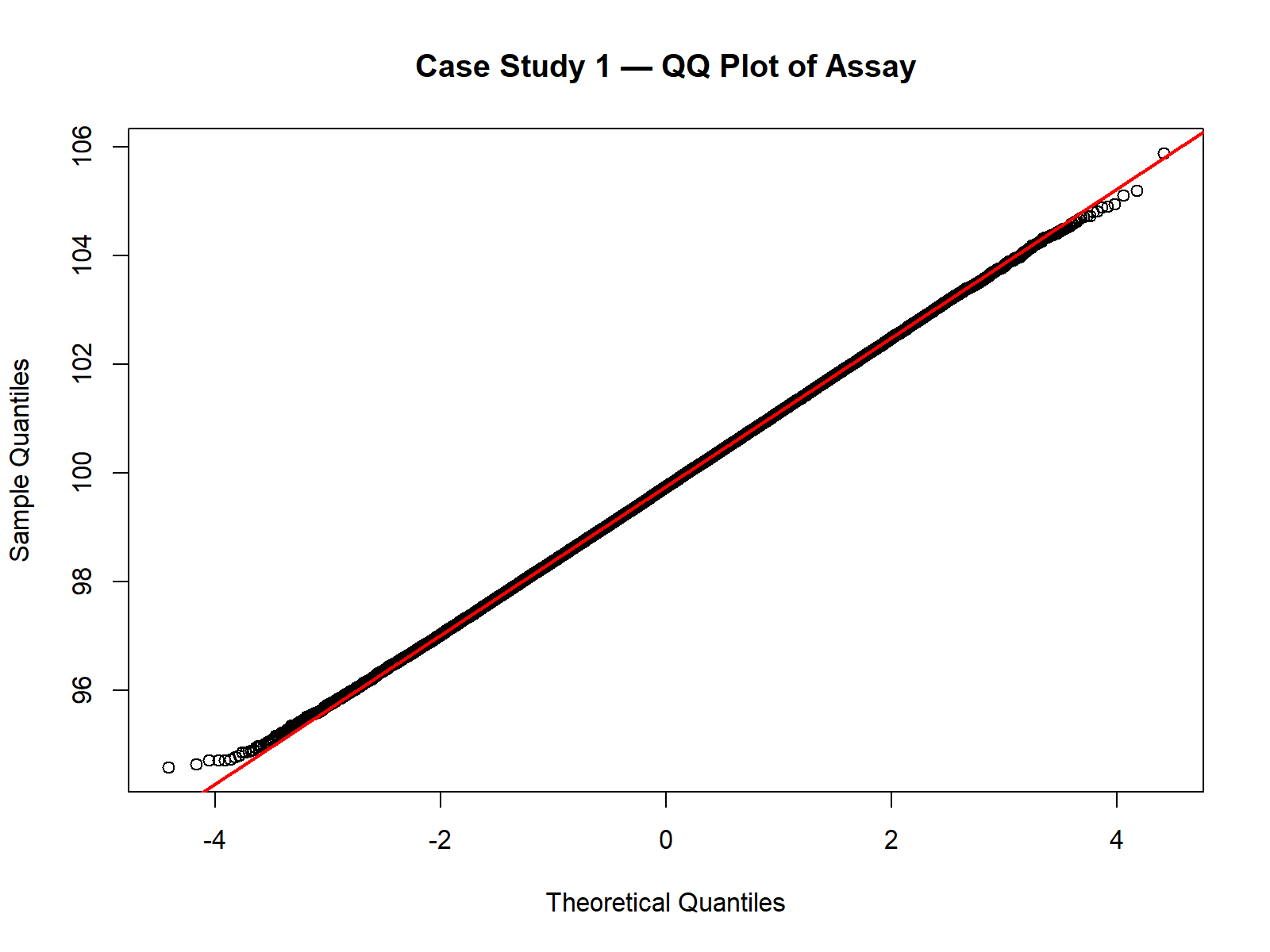

# 6) QQ plot for normality check

qqnorm(Assay, main = "Case Study 1 — QQ Plot of Assay")

qqline(Assay, col = "red", lwd = 2)

# 7) Probability of OOS

p_out <- mean(Assay < 98 | Assay > 102)

# 8) Capability index vs 98–102 (normality assumption)

USL <- 102; LSL <- 98

Cpk <- min((USL - mean_assay) / (3 * sd_assay),

(mean_assay - LSL) / (3 * sd_assay))

list(mean_assay = mean_assay, sd_assay = sd_assay, p_out = p_out, Cpk = Cpk)

p_out): 14.95%Summary of simulated assay results (N = 100,000):

| Statistic | Value |

|---|---|

| Mean | 99.75 |

| Standard Deviation | 1.36 |

| 5th Percentile | 97.53 |

| 95th Percentile | 101.96 |

| Minimum (simulated) | 95.01 |

| Maximum (simulated) | 104.56 |

| Probability of OOS | 14.95% |

| Capability Index (Cpk) | 0.43 |

These values indicate a process with excessive variability and a non-negligible risk of producing batches outside specifications.

In this Monte Carlo framework, the estimated probability of OOS (p_out) represents a quantitative risk of non-compliance, providing a direct numerical view of process capability under GMP.

Note: This dataset was chosen deliberately to illustrate how Monte Carlo simulations can reveal a process that is not in control.

In a real GMP context, results like these would trigger a root cause investigation and corrective actions to reduce variability and improve process centering.

Cpk was calculated as:

\[Cpk = \min \left( \frac{USL - \mu}{3\sigma}, \frac{\mu - LSL}{3\sigma} \right)\]Cpk = min( (USL - μ)/(3*σ), (μ - LSL)/(3*σ) )

Note: The closed-form Cpk assumes approximate normality. For skewed or non-normal data, percentile-based indices or Monte Carlo percentiles are more robust.

In GMP reports, it is often recommended to present both parametric indices (like Cpk) and percentile-based indices,

to ensure robustness against deviations from normality.

Reminder: Unlike the “ideal” scenarios shown earlier (low p_out, high Cpk),

this case study was selected to demonstrate how Monte Carlo simulation can highlight an at-risk process and guide GMP decision-making.

This approach can be extended to future case studies, such as:

This quantitative approach supports risk-based decision-making and can be documented in validation or continued process verification reports.

Suppose variability of API weight is reduced from sd = 1.2 mg → sd = 0.8 mg

(e.g., by better control of blending and compression).

Re-running the simulation (after process improvement, N = 100,000) yields:

| Statistic | Value |

|---|---|

| Mean | 99.75 |

| Standard Deviation (SD) | 0.93 |

| Probability of OOS | 5.0% |

| Capability Index (Cpk) | 0.63 |

Comparison: Before vs After Process Improvement

| Statistic | Before (sd=1.2 mg) | After (sd=0.8 mg) |

|---|---|---|

| Mean | 99.75 | 99.75 |

| Standard Deviation (SD) | 1.36 | 0.93 |

| Probability of OOS | 14.95% | 5.0% |

| Capability Index (Cpk) | 0.43 | 0.63 |

This demonstrates how Monte Carlo can quantify the benefit of CAPA actions,

providing objective evidence that process improvements significantly reduce the risk of non-compliance.

🔎 Regulatory Note:

This type of Monte Carlo analysis aligns with the ICH Q9(R1) principles of risk management,

and can support documentation in Process Validation Stage 3 (Continued Process Verification)

as recommended in FDA and EMA guidelines.

These results illustrate how Monte Carlo simulation provides not only descriptive statistics, but also probabilistic evidence of compliance risk,

which can be directly incorporated into GMP decision-making and regulatory documentation.

In the next chapter, we expand this quantitative perspective by linking Monte Carlo outputs to systematic decision-making and risk management strategies in GMP environments.

| ← Previous: Analysis of Results | ▲ Back to top | Next → Case Study 2 — Dissolution with Noyes–Whitney Law |